Sampson Plastics One Stop Service

One stop "Art to Part" service

Increasing numbers of companies are finding that customers want to send drawings and design data via broadband e-mail - or by post on a disc. It also seems that advances in CAD/CAM technology have filtered down to all sectors of industry, and if businesses do not have a grasp of this technology, it is likely that they will lose work. One small company to appreciate this fact is Ashford-based Sampson Plastics, which not only has a grasp of current technology, but is also maximizing its potential by producing tooling and moulds at very competitive prices - and it winning additional work as a result.

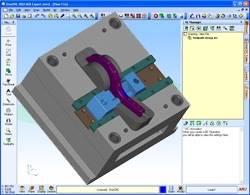

When company director Dave Sampson first invested in a popular CAD/CAM system a few years ago, he found that it was not the highly productive tool he had anticipated; and when an upgrade package also fell significantly short of his expectations, he sought an alternative system.It was only when Mr Sampson began using this new software that the benefits of CAD/CAM really became apparent; the replacement was a modular suite of software from OneCNC UK.

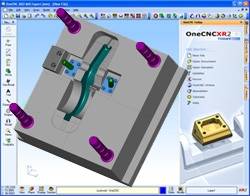

This software - the sixth generation from OneCNC, known as XR2 - is fully integrated and unified, and it uses CAM 'wizards' for all toolpath-related operations. These guide the programmer through the process of setting up the tooling and toolpath strategies that are necessary for the efficient machining of anything from a simple two-axis job right up to five-axis positional work. Sampson Plastics' CAD/CAM programmer, Richard Austen, is putting the software's features to good use as part of the company's one-stop 'art to part' service.

In fact, most of the injection-moulded part and tool design that Mr Austen undertakes has come as a direct result of the company being able to approach customers with a viable proposition for updating their product lines. "However, achieving this enviable position is only possible because the software is intuitive and productive, to the extent that redesigning tooling and moulds can now be done at a very competitive price, which was not the case previously," says Mr Austen.

Sampson Plastics

Churchfield Way

Wye

Ashford

TN25 SEQ

OneCNC Updates

OneCNC XR9 Release 74.80

Apr 01 2024

OneCNC XR9 Release 74.77

Feb 28 2024

OneCNC XR9 Release 74.68

Feb 13 2024